INDUCTION HEATING

-

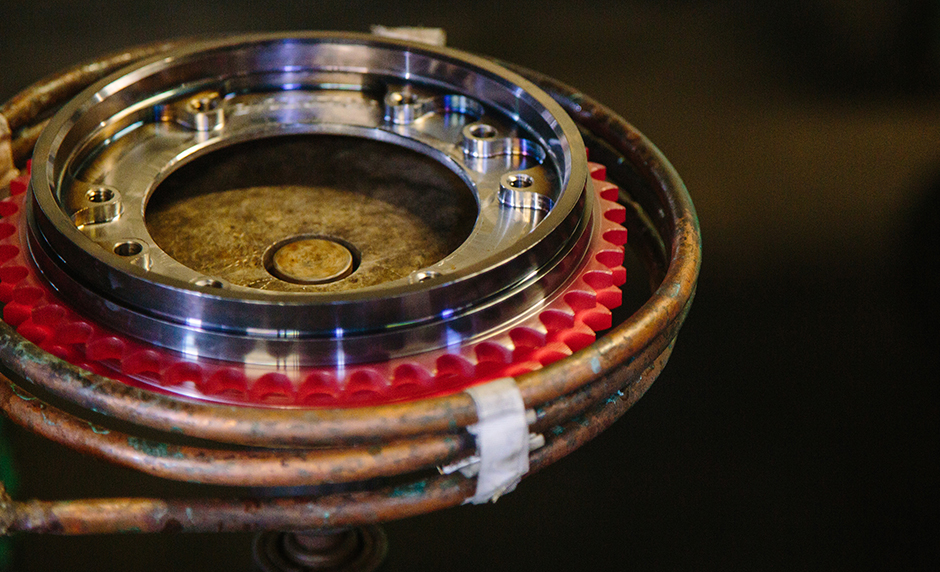

The primary advantage of Induction Heating is that heating of only selected areas of the parts can be achieved. This provides for selective heat treatments including hardening, surface hardening, and annealing.

-

In Induction Heating, a high frequency current is passed through a coil surrounding the part to be treated – resulting in heating by electro-magnetic induction. The heat-affected zone can be controlled by the configuration of the induction coil, the orientation of the part in the coil, the frequency and amount of power used, and by rotating or scanning the length of the part. The time required to heat the part to obtain a complete austenitic transformation is brief, typically only a few seconds for a surface hardening application. Once the part has been heated, it can be quenched or slow cooled as required by the particular heat treatment.