MILITARY / DEFENSE

American military technology is the world’s finest. At Thermal-Vac, we intend to keep it that way! Our experienced contract managers meet all of DPAS ratings.

Learn More

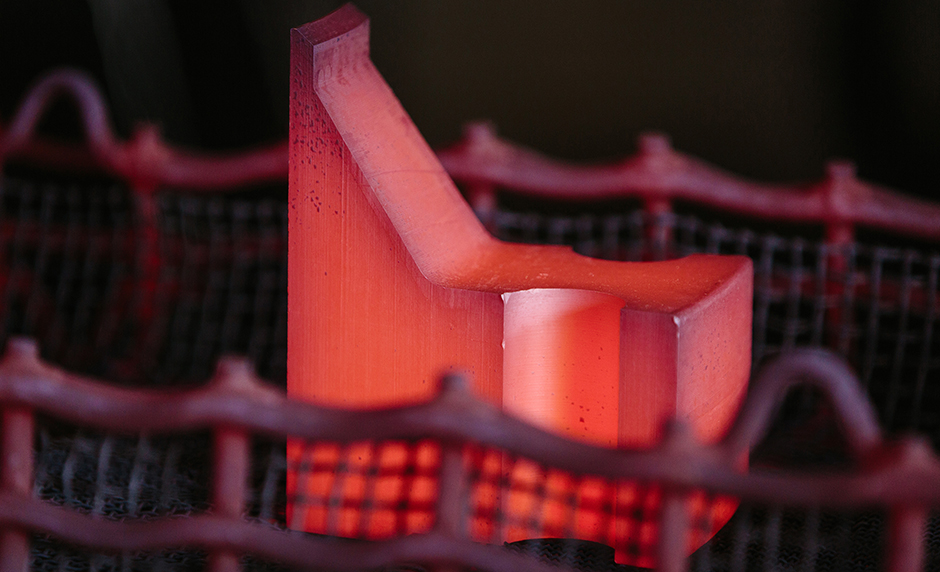

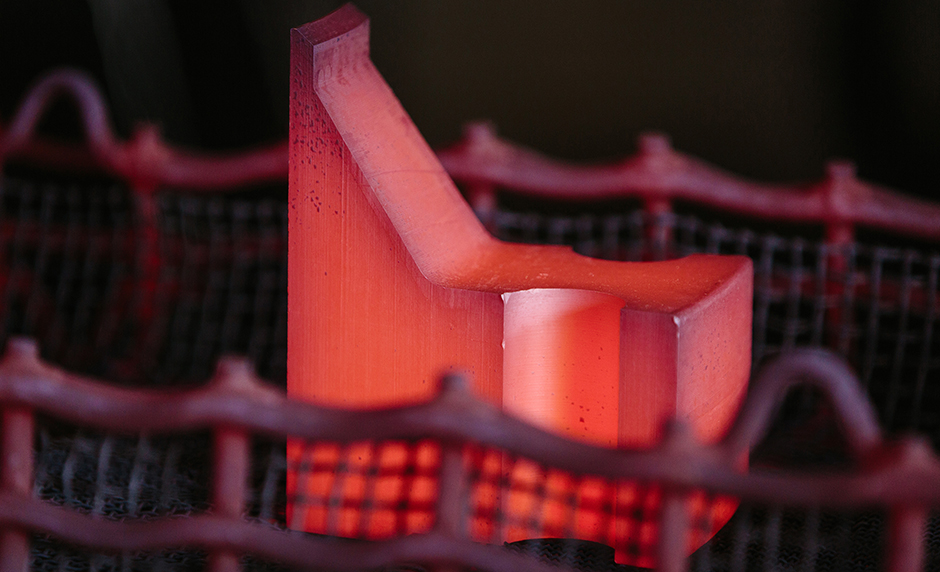

Annealing is a process involving heating and cooling, usually applied to produce softening of the metal to facilitate machining or forming operations. The term also refers to treatments intended to alter mechanical or physical properties, produce a definite microstructure, or remove gases. The temperature of the operation and the rate of cooling depend upon the material being annealed and the purpose of the treatment.

Normalizing is a process in which steel is heated to a temperature above the transformation range and then cooled in still air. The purpose of the treatment is to obliterate the effects of any previous heat treatment and to insure a good result on re-heating for hardening or full annealing.

Hardening and Tempering are used to provide the best combination of hardness, strength, and toughness in a steel for a given engineering purpose. This treatment consists of heating the steel above the transformation range, holding for a long enough time to insure uniform temperature and solution of the carbon and alloying elements in an austenitic microstructure, followed by rapid cooling (quenching) to a fully martensitic structure. The cooling medium can be air, oil, water, molten salt, fluidised bed, or a gas such as argon or nitrogen. Upon completion of hardening, the steel is in it’s hardest but most brittle condition. It is necessary to perform a subsequent tempering or drawing or process to produce a softer but much tougher condition.

More Information

Tempering, sometimes called Drawing, is the process of re-heating hardened steels to reduce hardness and increase toughness. The tempering temperature depends upon the desired properties and the purpose for which the steel is to be used. Increasing the tempering temperature will reduce the hardness of the steel while increasing the toughness.

More Information

American military technology is the world’s finest. At Thermal-Vac, we intend to keep it that way! Our experienced contract managers meet all of DPAS ratings.

Learn More

Ferocious temperatures, extreme environments, and exacting tolerances make aerospace applications incredibly difficult, though this is precisely where we excel.

Learn MoreThermal-Vac has received certified recognition by these top accreditation programs.

Heat Treating