Vacuum Heat Treating

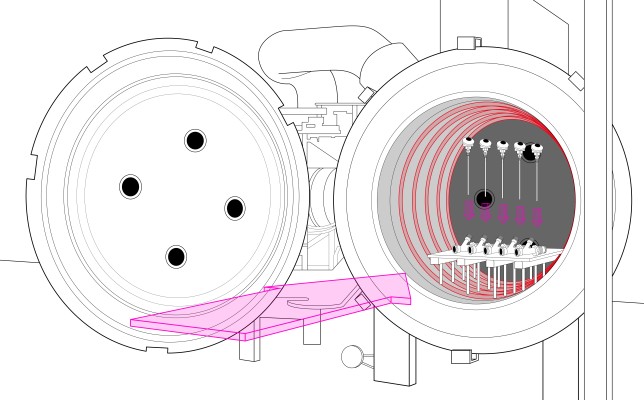

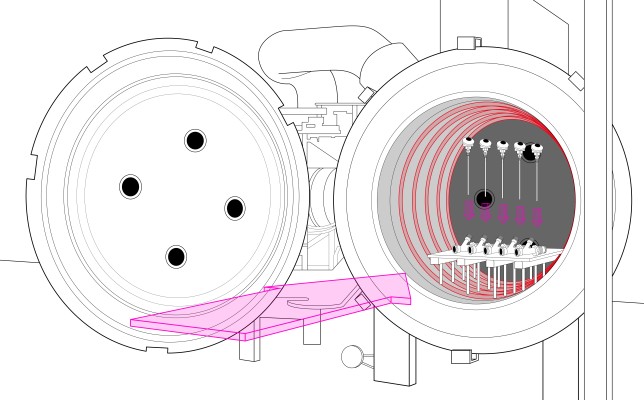

How it works

Step 2

Pull a vacuum on the furnace to ensure clean processing of parts.

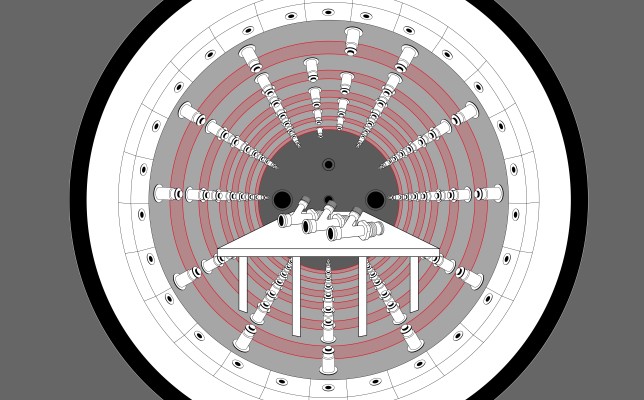

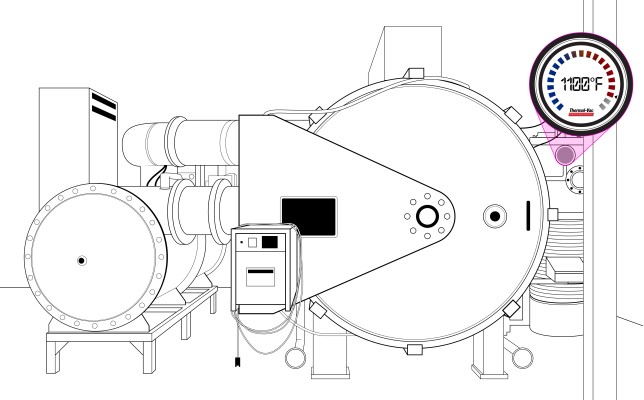

Step 3

Heat furnace to appropriate temperature profile to ensure properly heat treated parts.Vacuum heat treating is clean, easy to control, and safe. The results are clean, shiny parts with minimal distortion and which require comparatively little post-treatment finishing and cleaning.

Benefits of Vacuum Heat Treating

- Virtually eliminates oxidation problems by performing the operation in a vacuum atmosphere

- Precisely control heat-up and quench rates to minimize heat-induced distortion

- Produce full hardness in steels by easily changing cooling rates, even within a single cycle, to enable gas-quenching operations

- Does not produce toxic or combustible waste gases, making it safer and more environmentally friendly than many liquid-quenching processes

Quality of work and passion for what we do is what drives us.

WHERE Heat Treating WORKS

Aerospace

Ferocious temperatures, extreme environments, and exacting tolerances make aerospace applications incredibly difficult, though this is precisely where we excel.

Learn More

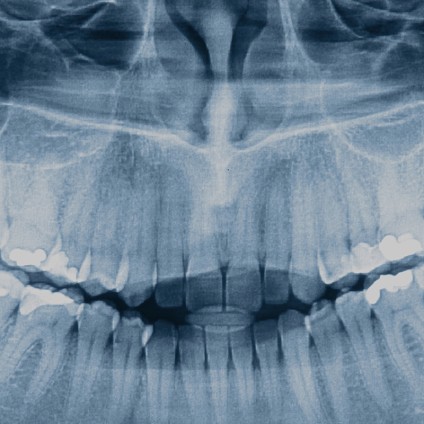

Medical / Dental

Some of the ways we provide world-class service to the medical industry include: Brazing of Dissmilar Metals (Metal to Ceramic, Titanium) High Temperature Brazing and Heat Treating (Temperatures Above 2400°F) Brazing to some of the most stringent cleanliness standards in the industry

Learn MoreACCREDITATION

Thermal-Vac has received certified recognition by these top accreditation programs.

-

Heat Treating

-