Aluminum Dip Brazing

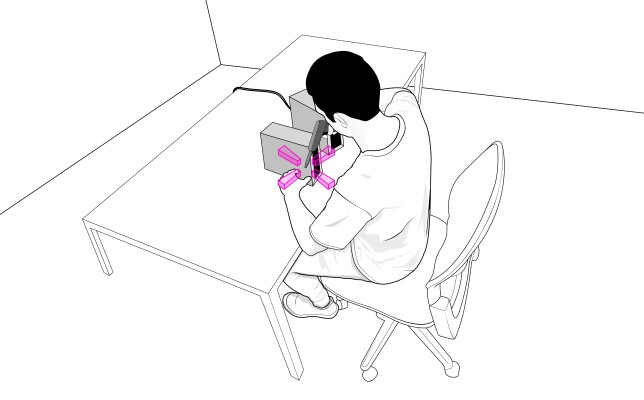

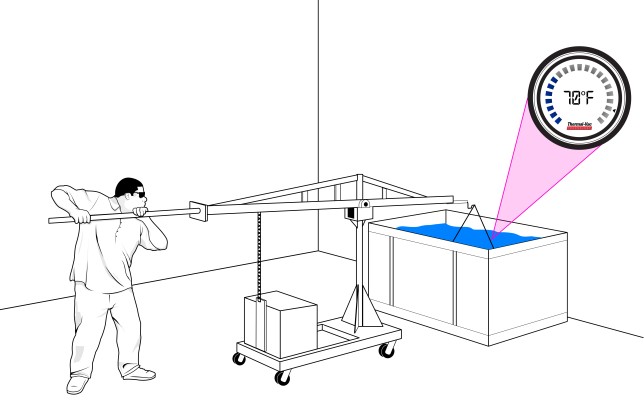

How it works

Step 2

Preheat parts in an air furnace to prepare for dip brazing.

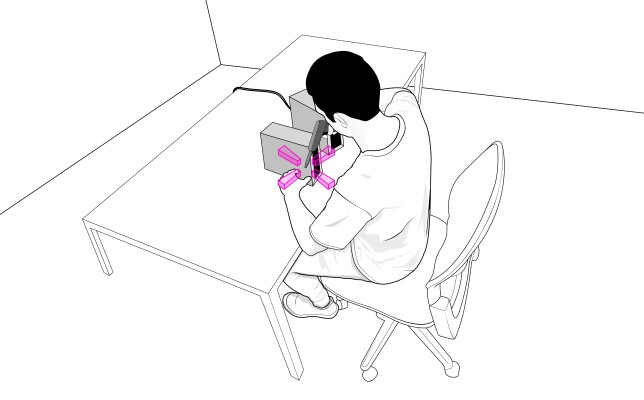

Step 3

Immerse parts in molten salt bath to melt and flow braze alloy.

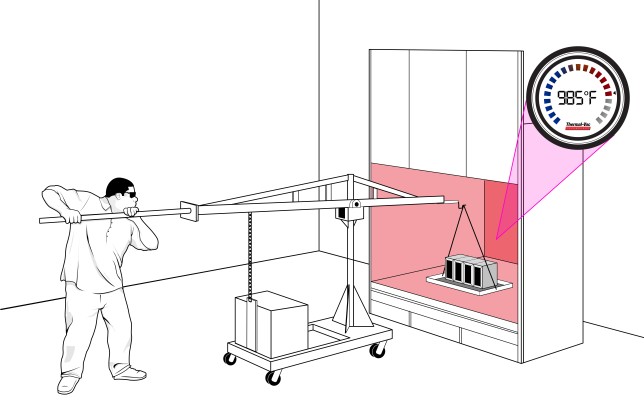

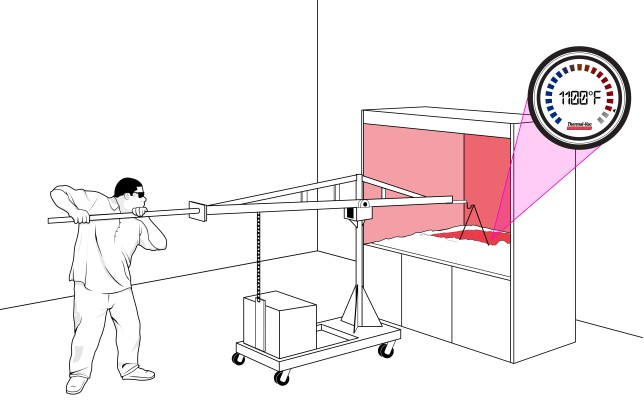

Step 4

Remove from bath to quench, clean and cool parts, aging in an air furnace as needed.

Benefits of Aluminum Dip Brazing

- It’s clean. The molten salts act as a flux, and protect the joints from oxidation. Once the residual salts are washed away you’re left with a beautiful product which requires little in the way of final cleaning or adjustments.

- It’s cost-effective. Aluminum Dip Brazing usually requires no expensive jigs or tooling. Instead, parts are designed to be self-locating and self-fixturing.

Quality of work and passion for what we do is what drives us.

WHERE Brazing WORKS

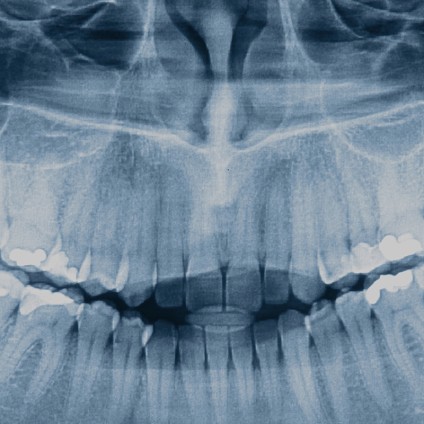

Medical / Dental

Some of the ways we provide world-class service to the medical industry include: Brazing of Dissmilar Metals (Metal to Ceramic, Titanium) High Temperature Brazing and Heat Treating (Temperatures Above 2400°F) Brazing to some of the most stringent cleanliness standards in the industry

Learn More

Engines / Propulsion

Our high-precision brazing, plating, heat treating, and coating/finishing products have been tested and proven in the world’s most severe torture chamber – the guts of a rocket engine.

Learn MoreACCREDITATION

Thermal-Vac has received certified recognition by these top accreditation programs.

-

Heat Treating

-