Aluminum Dip Brazing

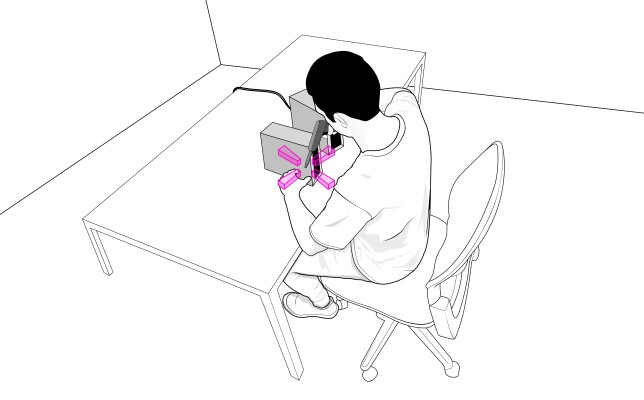

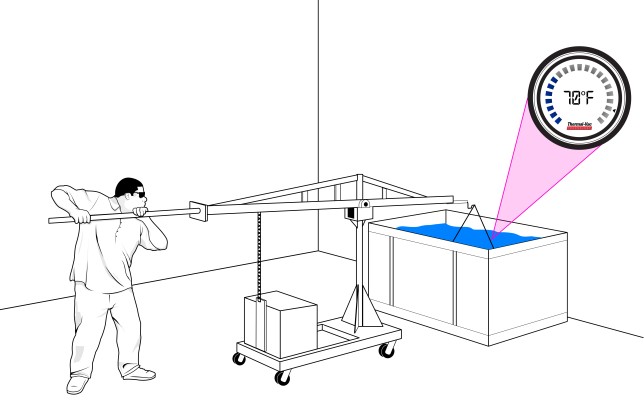

How it works

Step 2

Preheat parts in an air furnace to prepare for dip brazing.

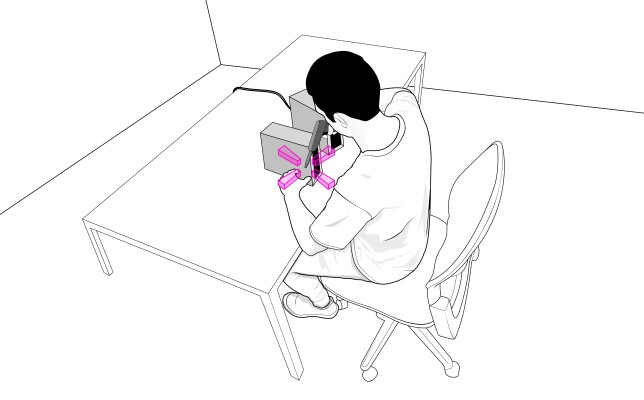

Step 3

Immerse parts in molten salt bath to melt and flow braze alloy.

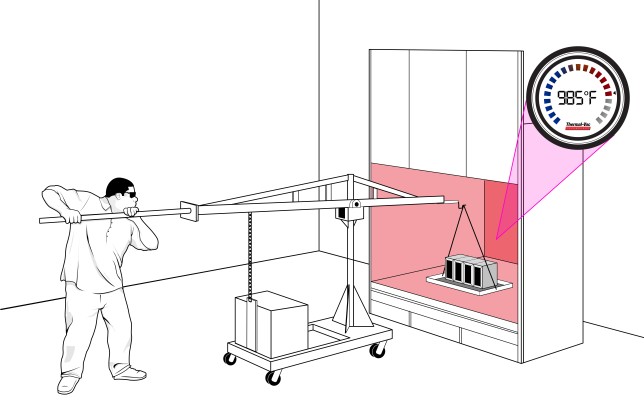

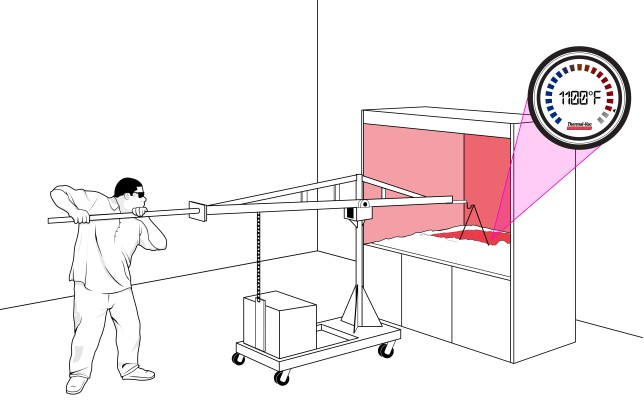

Step 4

Remove from bath to quench, clean and cool parts, aging in an air furnace as needed.

Benefits of Aluminum Dip Brazing

- It’s clean. The molten salts act as a flux, and protect the joints from oxidation. Once the residual salts are washed away you’re left with a beautiful product which requires little in the way of final cleaning or adjustments.

- It’s cost-effective. Aluminum Dip Brazing usually requires no expensive jigs or tooling. Instead, parts are designed to be self-locating and self-fixturing.

Quality of work and passion for what we do is what drives us.

WHERE Brazing WORKS

Aerospace

Ferocious temperatures, extreme environments, and exacting tolerances make aerospace applications incredibly difficult, though this is precisely where we excel.

Learn More

MILITARY / DEFENSE

American military technology is the world’s finest. At Thermal-Vac, we intend to keep it that way! Our experienced contract managers meet all of DPAS ratings.

Learn MoreACCREDITATION

Thermal-Vac has received certified recognition by these top accreditation programs.

-

Heat Treating

-