Tempering

How it works

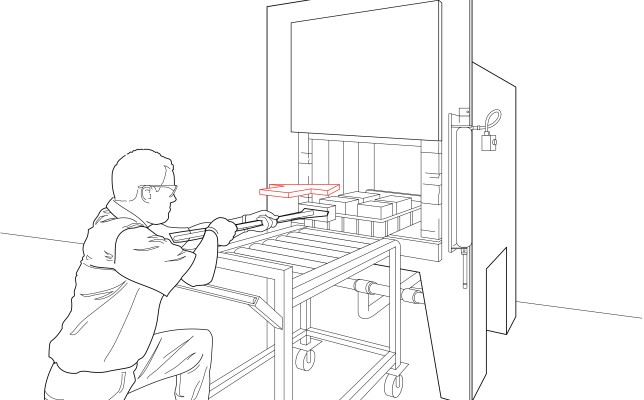

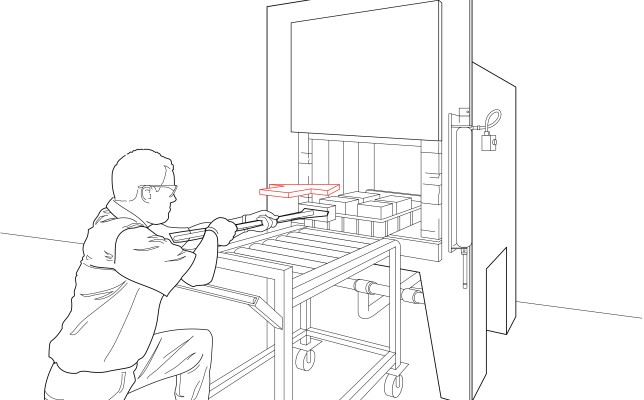

STEP 2

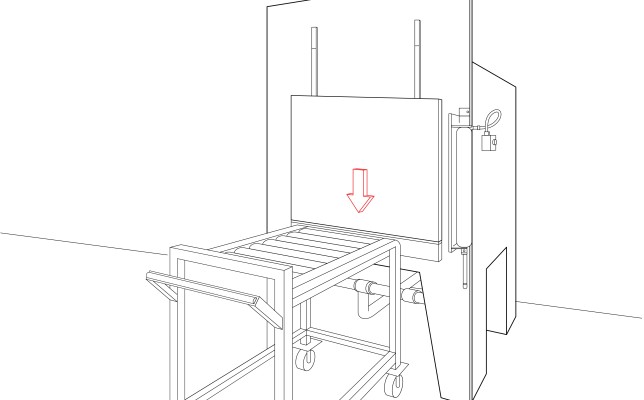

Parts are heated to a specific temperature to provide the required final hardness (temper).

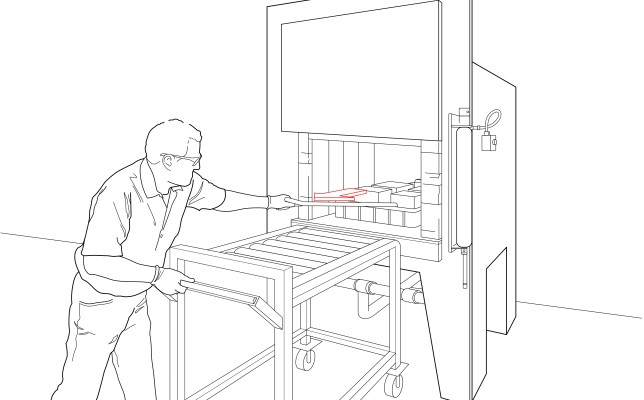

STEP 3

Parts are removed from the furnace to continue to subsequent processing such as cleaning and inspection.Tempering, sometimes called Drawing, is the process of re-heating hardened steels to reduce hardness and increase toughness. The tempering temperature depends upon the desired properties and the purpose for which the steel is to be used. Increasing the tempering temperature will reduce the hardness of the steel while increasing the toughness.

Quality of work and passion for what we do is what drives us.

WHERE WORKS

Aerospace

Ferocious temperatures, extreme environments, and exacting tolerances make aerospace applications incredibly difficult, though this is precisely where we excel.

Learn More

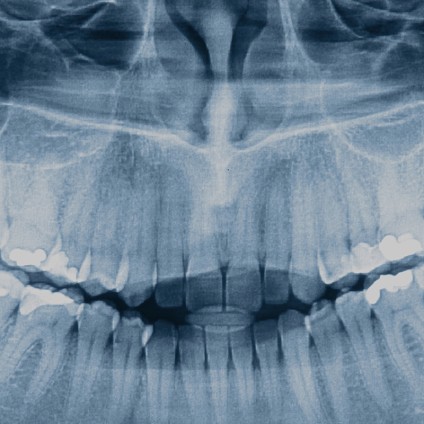

Medical / Dental

Some of the ways we provide world-class service to the medical industry include: Brazing of Dissmilar Metals (Metal to Ceramic, Titanium) High Temperature Brazing and Heat Treating (Temperatures Above 2400°F) Brazing to some of the most stringent cleanliness standards in the industry

Learn MoreACCREDITATION

Thermal-Vac has received certified recognition by these top accreditation programs.

-

Heat Treating

-