In Metallurgy, annealing refers to a specific kind of heat treatment that physically changes the properties of a material to increase its ductility and reduce its hardness, in order to make it easier to work with. Annealing heats a base material above its recrystallization temperature, which allows it to maintain in a workable state and temperature before cooling.

Physical Change

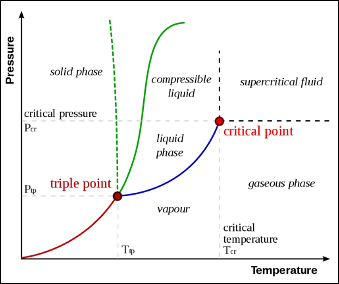

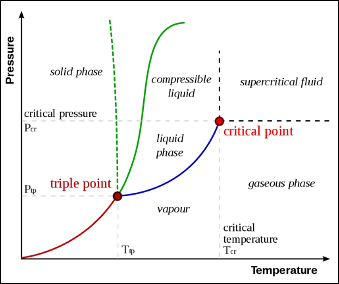

Annealing many alloys, commonly carbon steel, its physical properties change based on the heating and cooling rate. Technicians can work with the materials during increased heating or cooling, after the process has altered the structure. Metallurgists will use phase diagram (below) during the process to better understand the material’s state between harder and more brittle to softer and more ductile.

Benefits and Process

Annealing restores “ductility” after cold working and enables technicians with the ability to work with the base material(s) longer without them cracking or breaking. Sometimes annealing is used to release mechanical stress that has developed over time due to grinding, machining, and general wear-and-tear. Overall, the annealing process benefits technicians’ ability to soften a metal, improve machinability, and enhance electrical conductivity.

Annealing has three processes: recovery, recrystallization, and grain growth/normalization.

In the Recovery Stage, a large furnace or oven is used to raise the base materials to a temperature that relieves its internal stresses. During the Recrystallization Stage, the base materials are heated above a recrystallization temperature point, but below its melting point. The result will cause new grains to form, absent of any preformed stress. At the Grain Growth Stage or Normalization, new grains develop and the technician controls their growth by cooling the material at a specific rate. This specialization results in a higher ductility and lower hardness. Additional processes and further alter the base materials’ mechanical properties after the process has finished.

In steel, annealing takes place at 1000°F – 1200°F, so there is no crystal structure change. Intermediate annealing is carried out at 1200°F – 1400°F in which some transformation occurs. Full annealing involves completely altering the materials at 1500°F – 1700°F.

Annealing vs. Tempering

Essentially, the main difference between annealing and tempering is how the materials are treated. Technicians use tempering to increase the toughness of steel because steel, while extremely hard, is too brittle to work with. Tempering is commonly done after hardening to reduce excess hardness.

Technicians use tempering to alter and change steel’s ductility, hardness, strength, structural stability, and toughness.

Thermal-Vac Technology utilizes state-of-the-art equipment to perform complicated brazing, specialty heat-treating, and metallographic analysis.

Contact us today to learn more about what are able to deliver for you.