Gas Nitriding

How it works

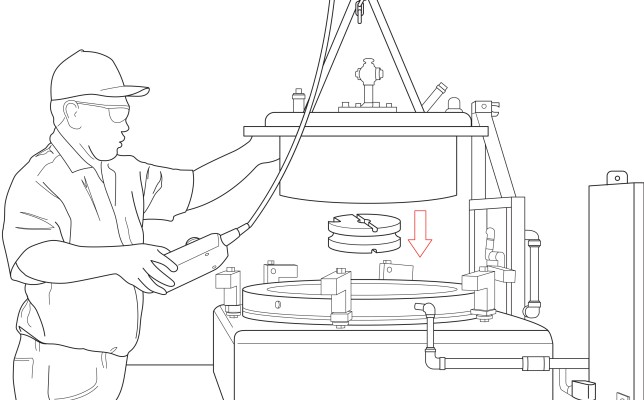

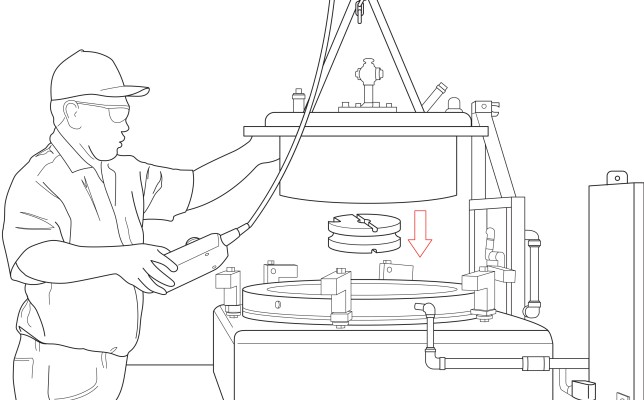

STEP 2

Parts are heated to nitriding temperature, typically 975 degrees Fahrenheit. An atmosphere created using ammonia gas is introduced into the furnace. The atmosphere provides nitrogen which diffuses into the surface of the metal creating a very hard, thin nitride case.

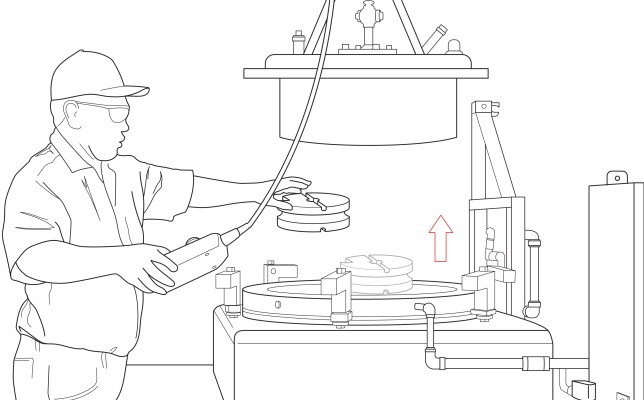

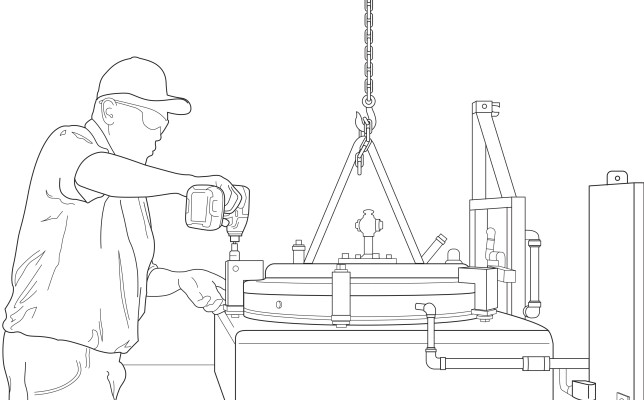

STEP 3

Parts are cooled and then removed from the furnace to continue to subsequent processing such as cleaning and inspection.Gas Nitriding consists of subjecting machined and heat-treated steel, free from surface decarburization, to the action of a nitrogenous medium, usually ammonia gas, at a temperature of approximately 950°F to 1050°F, creating a very hard surface. The surface hardening effect is due to the absorption of nitrogen, and subsequent heat treatment if the steel is unnecessary. The case is less than .020 inch deep and the highest hardness exists in the surface layers to a depth of only a few thousandths of an inch. Because of the low temperatures required for Gas Nitriding, distortion is very low compared to other Case Hardening processes.

Because Gas Nitriding is carried out at a relatively low temperature, it is advantageous to use quenched and tempered steel as the base material. This gives a strong, tough core with an intensely hard wear-resisting case — much harder than can be obtained by quench hardened or carburized steel.

Quality of work and passion for what we do is what drives us.

WHERE WORKS

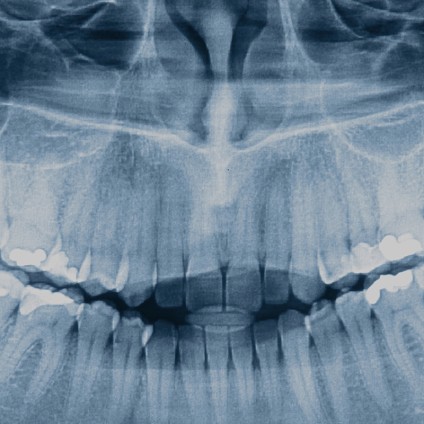

Medical / Dental

Some of the ways we provide world-class service to the medical industry include: Brazing of Dissmilar Metals (Metal to Ceramic, Titanium) High Temperature Brazing and Heat Treating (Temperatures Above 2400°F) Brazing to some of the most stringent cleanliness standards in the industry

Learn More

Aerospace

Ferocious temperatures, extreme environments, and exacting tolerances make aerospace applications incredibly difficult, though this is precisely where we excel.

Learn MoreACCREDITATION

Thermal-Vac has received certified recognition by these top accreditation programs.

-

Heat Treating

-